Introduction

Water is life, and ensuring its purity is more critical than ever in 2025. With growing populations, industrial demands, and environmental challenges, Water Treatment Plants (WTPs) have become the backbone of clean water supply systems worldwide. But what exactly is a WTP Treatment Plant, and why should you care? In this ultimate guide, we’ll dive deep into the world of WTPs, exploring their processes, benefits, technologies, and their pivotal role in delivering safe, potable water. Whether you’re a homeowner, policymaker, or industry professional, this blog will answer all your questions about WTP Treatment Plants and their significance in sustainable water management.

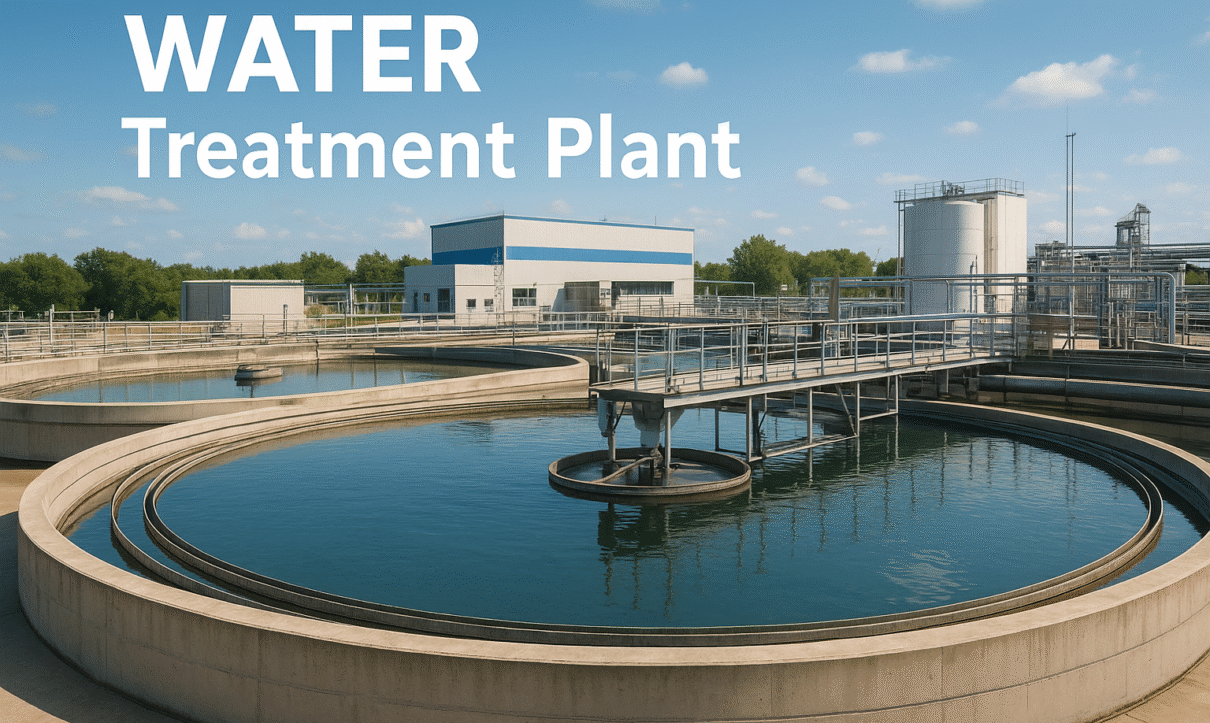

What is a WTP Treatment Plant?

A Water Treatment Plant (WTP) is a facility designed to purify raw water from natural sources like rivers, lakes, or groundwater, making it safe for human consumption and industrial use. These plants remove contaminants, sediments, and harmful microorganisms through a series of physical, chemical, and biological processes. In 2025, WTPs are not just about purification—they incorporate advanced technologies to ensure efficiency, sustainability, and compliance with stringent environmental regulations.

Why WTP Treatment Plants Matter

- Public Health: WTPs eliminate pathogens and pollutants, preventing waterborne diseases like cholera and typhoid.

- Environmental Protection: They reduce the ecological impact of untreated wastewater.

- Sustainable Development: WTPs support water recycling and conservation, crucial for water-scarce regions.

- Industrial Efficiency: Clean water is vital for industries like manufacturing, agriculture, and power generation.

By understanding WTPs, you can appreciate their role in ensuring clean water access for communities and industries alike.

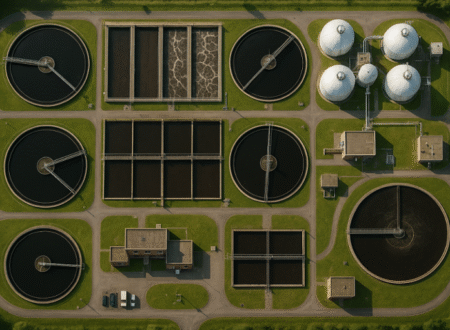

How Do WTP Treatment Plants Work?

The operation of a WTP Treatment Plant involves multiple stages, each designed to tackle specific impurities. Here’s a detailed breakdown of the process:

1. Screening

The journey begins with screening, where large debris like leaves, sticks, and plastics are removed from raw water using coarse screens. This step protects downstream equipment from damage.

2. Coagulation and Flocculation

Next, chemicals called coagulants (e.g., alum or ferric chloride) are added to bind small particles into larger clumps called flocs. During flocculation, gentle mixing helps these flocs grow, making them easier to remove.

3. Sedimentation

The water then flows into sedimentation tanks, where gravity pulls the heavy flocs to the bottom, forming sludge. The clearer water is skimmed off the top for further processing.

4. Filtration

Filtration is the heart of a WTP. Water passes through layers of sand, gravel, or activated carbon to remove finer particles, bacteria, and organic matter. Advanced WTPs in 2025 often use membrane filtration (e.g., ultrafiltration or reverse osmosis) for superior purity.

5. Disinfection

To kill remaining pathogens, disinfectants like chlorine, ozone, or UV radiation are applied. Chlorination is common, but ozone and UV are gaining traction for their eco-friendly profiles.

6. pH Adjustment and Stabilization

Before distribution, the water’s pH is adjusted, and chemicals like lime are added to prevent pipe corrosion and ensure stability during transport.

7. Sludge Management

The sludge from sedimentation and filtration is treated separately, often through dewatering or anaerobic digestion, to minimize environmental impact.

This multi-stage process ensures that water meets global safety standards, such as those set by the World Health Organization (WHO) or local regulatory bodies.

Types of WTP Treatment Plants

WTPs vary based on their purpose, source water, and treatment technologies. Here are the main types in 2025:

1. Municipal WTPs

These plants treat water for entire cities, focusing on potable water supply. They handle large volumes and prioritize cost-effectiveness and reliability.

2. Industrial WTPs

Designed for industries like pharmaceuticals, food processing, or power plants, these WTPs produce ultra-pure water tailored to specific industrial needs.

3. Desalination WTPs

In coastal or arid regions, desalination WTPs convert seawater into freshwater using reverse osmosis or thermal distillation, addressing water scarcity.

4. Mobile or Compact WTPs

Portable WTPs are deployed in emergencies (e.g., natural disasters) or remote areas, offering quick and flexible water treatment solutions.

5. Zero Liquid Discharge (ZLD) WTPs

Popular in 2025, ZLD WTPs recycle nearly 100% of water, minimizing waste and supporting sustainability goals.

Each type is tailored to its context, ensuring optimal performance and compliance with regulations.

Why WTP Treatment Plants Are Crucial in 2025

In 2025, WTP Treatment Plants are more vital than ever due to several global trends:

- Urbanization: Rapid urban growth increases water demand, putting pressure on WTPs to scale up.

- Climate Change: Droughts and erratic rainfall make water treatment and recycling essential.

- Industrial Growth: Industries require high-quality water, driving demand for specialized WTPs.

- Regulatory Standards: Stricter water quality regulations push WTPs to adopt cutting-edge technologies.

- Sustainability Goals: WTPs align with global initiatives like the UN’s Sustainable Development Goals (SDG 6: Clean Water and Sanitation).

By addressing these challenges, WTPs ensure a reliable supply of clean water for a growing world.

Advanced Technologies in WTP Treatment Plants in 2025

Innovation is transforming WTPs, making them more efficient and eco-friendly. Here are some cutting-edge technologies shaping the industry:

1. Membrane Bioreactors (MBRs)

MBRs combine biological treatment with membrane filtration, offering compact and highly effective purification.

2. Nanotechnology

Nanofilters and nanomaterials remove contaminants at the molecular level, improving water quality and reducing chemical use.

3. Smart Monitoring Systems

IoT-enabled sensors and AI monitor water quality in real-time, optimizing processes and reducing energy consumption.

4. Ozone and UV Disinfection

These methods are replacing chlorine in many WTPs due to their effectiveness and minimal environmental impact.

5. Energy-Efficient Systems

Solar-powered WTPs and energy recovery systems are reducing the carbon footprint of water treatment.

These advancements make WTPs more sustainable, cost-effective, and capable of meeting diverse water needs.

Benefits of WTP Treatment Plants

Investing in WTPs offers numerous advantages for communities, industries, and the environment:

- Safe Drinking Water: WTPs ensure water is free from harmful contaminants.

- Reduced Waterborne Diseases: Proper treatment eliminates pathogens, protecting public health.

- Environmental Conservation: Treated water reduces pollution in rivers and lakes.

- Water Reuse: WTPs enable recycling, crucial for water-scarce regions.

- Economic Growth: Reliable water supply supports industries and agriculture, boosting local economies.

Challenges Facing WTP Treatment Plants in 2025

Despite their importance, WTPs face several challenges:

- High Operational Costs: Advanced technologies and energy demands can be expensive.

- Aging Infrastructure: Many WTPs, especially in developing nations, require upgrades.

- Climate Variability: Unpredictable weather affects raw water quality and availability.

- Regulatory Compliance: Meeting evolving standards requires continuous investment.

- Public Awareness: Lack of understanding about WTPs can hinder community support.

Addressing these challenges requires collaboration between governments, industries, and communities.

How to Choose the Right WTP Treatment Plant for Your Needs

Selecting a WTP depends on several factors:

- Water Source: Surface water (rivers, lakes) or groundwater requires different treatment approaches.

- Purpose: Drinking water, industrial use, or wastewater recycling dictates the technology needed.

- Capacity: Ensure the plant can handle the required water volume.

- Budget: Balance upfront costs with long-term operational expenses.

- Sustainability: Opt for eco-friendly technologies like ZLD or solar-powered systems.

Consulting with water treatment experts and conducting feasibility studies can guide the decision-making process.

The Future of WTP Treatment Plants

Looking ahead, WTPs will play a pivotal role in global water security. By 2030, experts predict:

- Increased Automation: AI and IoT will streamline operations, reducing costs and errors.

- Decentralized WTPs: Smaller, localized plants will serve remote areas and reduce distribution losses.

- Circular Water Economy: WTPs will focus on recycling and reusing water to minimize waste.

- Climate Resilience: Plants will adapt to extreme weather through robust designs and backup systems.

These trends highlight the evolving role of WTPs in building a sustainable future.

FAQ

1. What is the difference between a WTP and a WWTP?

A WTP (Water Treatment Plant) purifies raw water for drinking or industrial use, while a WWTP (Wastewater Treatment Plant) treats sewage and industrial wastewater before releasing it into the environment or reusing it.

2. How much does a WTP Treatment Plant cost?

Costs vary based on capacity, technology, and location. Small-scale WTPs may cost $100,000–$500,000, while large municipal plants can run into millions. Contact water treatment providers for precise estimates.

3. Are WTPs environmentally friendly?

Modern WTPs use energy-efficient and low-waste technologies, making them increasingly sustainable. ZLD and solar-powered systems are prime examples.

4. Can WTPs treat contaminated groundwater?

Yes, WTPs use advanced filtration and chemical treatments to purify groundwater contaminated by heavy metals, pesticides, or other pollutants.

Conclusion

WTP Treatment Plants are the unsung heroes of clean water solutions in 2025. From removing contaminants to enabling water reuse, these facilities are vital for public health, environmental protection, and sustainable development. By embracing advanced technologies and addressing challenges, WTPs are paving the way for a water-secure future. Whether you’re curious about how they work or planning to invest in one, this guide has covered everything you need to know about WTP Treatment Plants.

Got more questions about WTPs or need help with water treatment solutions? you can know the thoughts with Shri Balaji Aqua